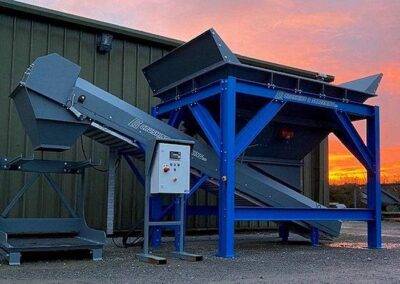

Bulk bag filling machine

A top-quality bulk bag filling machine designed specifically for the aggregate sector. With our cutting-edge technology and commitment to excellence, we provide solutions that streamline your bagging process. Our bulk bagging machines are highly versatile, capable of handling various aggregate materials such as sand, gravel, soil, compost, stone and more.

Accurate filling and weighing

These machines are engineered with precision to ensure accurate filling and weighing, minimizing material wastage. They are designed to operate at high speeds, maximizing productivity and throughput without compromising quality. We understand the demanding nature of the aggregate industry, which is why our bulk bagging machines are built to withstand rugged environments. Designed with the operator in mind, they feature intuitive controls and user-friendly interfaces. Easy to operate and maintain, we also provide training and support to ensure smooth integration into your production line.

Customizable options

Crushing & Screening ltd recognize that each aggregate operation has its own unique requirements. That is why we offer customizable options to tailor our machines to your specific needs. Whether you require additional features, specialized systems, or integration with existing equipment, we can provide the perfect solution. Do not let inefficient bagging processes hinder your productivity. Upgrade to our bulk bagging machines and experience improved efficiency, accuracy, and cost effectiveness. Contact us today to discuss your requirements, browse our YouTube channel to explore how our machines can benefit your aggregate operations. Our knowledgeable team is ready to assist you and provide the ideal bulk bagging solution for your business.

The bulk bag filling machine from Crushing & Screening Ltd includes a large capacity (circa 8m3) hopper, belt conveyor and a (optional) bag holder. Many more options and configurations are available to suit your requirements, these include weighing out and weighing in measuring systems. The bagging hopper is capable of handling many materials and integrates well into existing bagging plant systems.

The bulk bag fill sequence

The operator places a standard 4 looped (or sleeved) IBC bag onto the bag holder, then initiates the filling process by pressing the start button. An optional integrated weighing system will automatically stop the unit once the bag reaches the desired weight or volume.The filled IBC bag is then removed with a forklift and the process repeated. This machine is capable of filling a bag between 10-20 second’s (depending on material bulk density). This machine is suitable for all Aggregates, Wood Pellets, Compost, Bark, Rock Salt, Coal and many other products.

Installation

This model can be quickly and easily installed, onto the customers prepared base and ready to start production with the minimal amount of disruption. A robust bulk bag filling machine designed to work with a variety of products, including abrasive materials.

Options

- 800 or 650mm conveyor belt widths (to suit product).

- Fully lined (HDPE) hopper.

- Various fill speeds available.

- Soft start or inverter controls.

- Hopper access ladder, platform and handrails.

- Various bag hanger options to suit loop or tunnel bags.

- Separate or integral control panel.

- Remote control.

- Pre-manufacture colour choice in any RAL colour.

- Site installation.

- Bespoke additions on request.

For complete peace of mind, all new equipment is backed up by Crushing & Screening Ltd own manufacturers guarantee.

Please call +44 (0)1845 525288 to discuss your requirements in more detail.